Reducing Uncertainty in the Digital Implant Workflow

The digital revolution in dentistry has reshaped clinical workflows, enhancing precision and efficiency in delivering patient care. From intraoral scanning to computer-aided design (CAD) and 3D printing, the digital flow offers transformative potential. However, it also introduces variables and uncertainties at each stage, which, if unchecked, can cascade into significant errors. This blog summarizes key strategies to reduce these uncertainties and achieve consistent clinical outcomes.

The Critical Role of Intraoral Scanning

Intraoral scanning is the cornerstone of the digital dental workflow. Its accuracy directly influences all subsequent stages, including CAD design, 3D printing, and the fabrication of medical devices. Errors in this initial step can amplify through the process, highlighting the need for precise techniques and technologies.

Best Practices for Scanning Accuracy

- Operator Training: Even with advanced scanners, proper technique is essential. Operators must maintain consistent distances, follow systematic scanning paths, and capture all surfaces accurately.

- Environmental Conditions: Stable lighting, dryness, and patient preparation (e.g., cleaning teeth and managing moisture) are crucial for detailed imaging.

- Regular Calibration: Scanners require periodic maintenance and calibration to maintain performance and prevent distortions.

The Domino Effect of Errors

A small error in the scanning phase can snowball into significant issues downstream:

- CAD Design: Inaccurate scans result in flawed models, leading to devices that don’t fit or function properly.

- 3D Printing: Design errors carry over, compounded by potential calibration or material issues in printing.

- Milling: Even minor discrepancies in printed models can cause poorly fitting prosthetics, increasing time and cost.

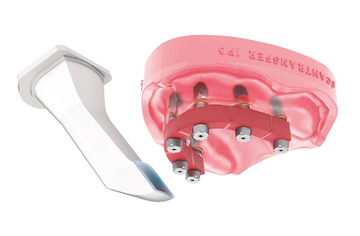

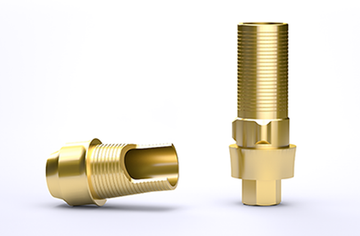

Technological Solutions: IPD ScanTransfer

Innovations like IPD ScanTransfer streamline data transfer between intraoral scanners and CAD software, reducing risks of transcription errors. Key benefits include:

- Accuracy: Ensures unaltered data transfer for precise modeling.

- Efficiency: Accelerates workflow by minimizing manual steps.

- Consistency: Maintains data integrity from scanning to production.

Advanced Protocols for Reducing Variables

- CSS Strategy: Employs consistent scanning paths to standardize results across operators and sessions.

- ReScan Procedure: Allows targeted rescanning of problematic areas, avoiding complete redo.

- DeBug Process: Identifies and resolves data anomalies early to prevent downstream issues.

Systematic Approach to Workflow Optimization

To mitigate errors and ensure reliable outcomes:

- Invest in ongoing training for dental professionals.

- Follow standardized protocols to minimize variability.

- Calibrate tools regularly to maintain peak performance.

- Leverage advanced technologies like ScanTransfer for error reduction.

- Implement stringent quality control measures at every stage.

Conclusion

A systematic, technology-driven approach can significantly reduce errors in the digital dental workflow, enhancing both clinical efficiency and patient satisfaction. By embracing innovations and rigorous practices, the dental industry moves closer to an error-free future, delivering predictable and high-quality outcomes.

Francesco Biaggini's insights provide a roadmap for leveraging digital dentistry's potential while addressing its inherent challenges.

Please download the full article here:

Reducing_Spheres_of_Uncertainly_in_the_Digital_Dental_Implant_Workflow.pdf